Important Properties of Gaskets

Today, we are going to talk about the important characteristic properties of gaskets. For given operating conditions, the selection of gaskets and the design of bolted flange joints (calculation of integrity and tightness) require several characteristic properties that characterize the mechanical and sealing behaviors of gaskets. To ensure the comparability, repeatability, and convertibility of these properties, they need to be determined through various standard test methods.

The main properties of gaskets include mechanical behavior properties, sealing behavior properties, and gasket stress.

Mechanical Behavior Properties

In the field of material performance research, the testing of the mechanical behavior properties of gaskets is crucial. Static compression and tensile tests are carried out on gasket samples at room temperature and high temperature in a testing machine. During the test, by precisely controlling the loading rate and ambient temperature, the deformation data of the sample under different loads are collected and recorded in real-time, and finally a complete load-deformation curve is drawn.

The shape of the load-deformation curve characterizes the mechanical behavior of the gasket.

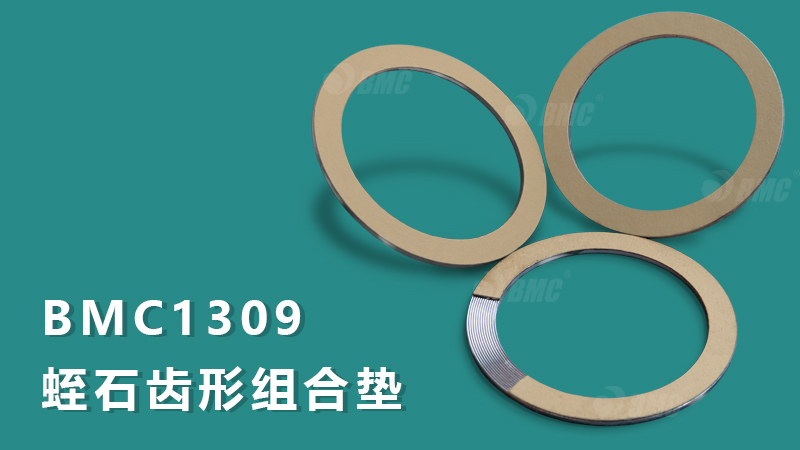

BMC1309: Suitable for high temperature and high pressure working conditions in pipeline flange sealing

Due to differences in gasket material properties (such as rubber, metal composite, etc.) and structural designs (such as wound type, corrugated type), the shape of the curve will vary significantly. The slope of the linear segment reflects the elastic modulus of the material, while nonlinear changes indicate plastic deformation or structural instability. Based on the load-deformation curve, certain mechanical properties of the gasket can be obtained, such as compressibility, resilience, compressive (collapse) strength, and tensile strength.

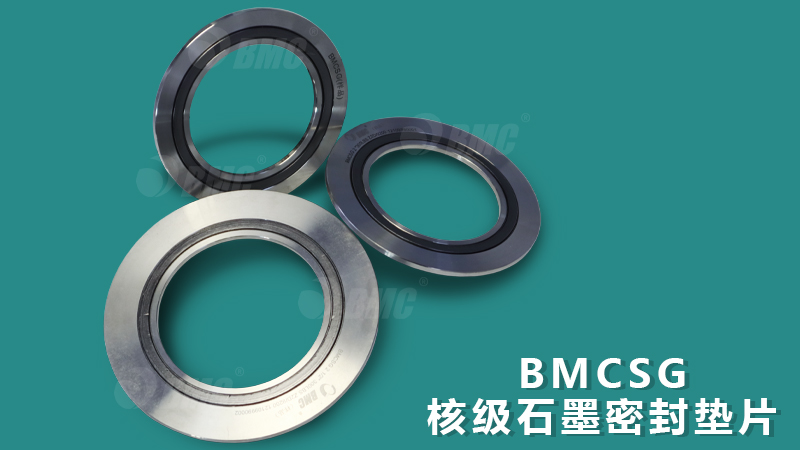

BMCSG: For high temperature resistant pipeline equipment flanges

In addition, the creep relaxation test is used to observe the deformation law of the gasket under long-term constant load, and the blow-out test simulates the critical conditions of seal failure under extreme working conditions. Through these tests, performance data such as creep relaxation rate, p×T value, and blow-out resistance can be obtained. These mechanical performance parameters are closely related to the sealing performance of the gasket and provide a core basis for the design of sealing structures and adaptation to working conditions.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! We will continue to talk about the important properties of gaskets in the next issue. See you next time!

Email:marketing@mybmc.com.cn

Email:marketing@mybmc.com.cn